-

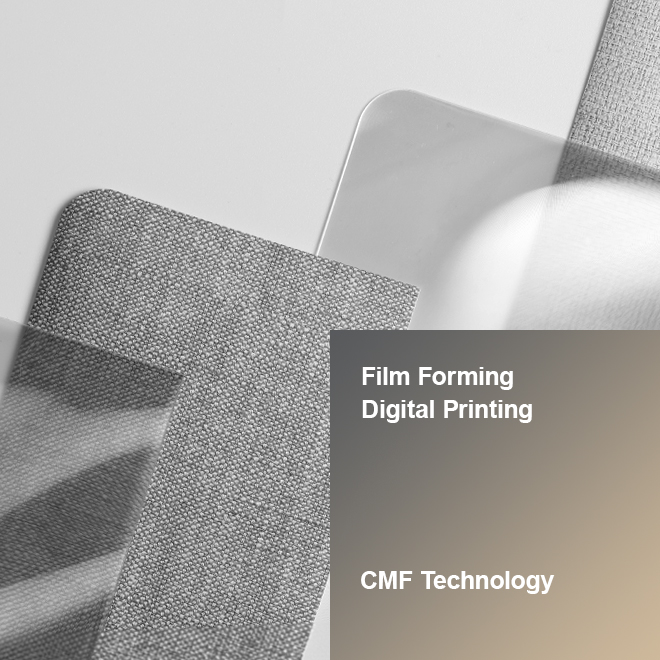

CMF(Color, Material, Finish) Technology

The May CMF (Color, Material, Finish) technology theme at hïda focuses on 3D wrapping and Injection molding. We introduce the characteristics, advantages, and disadvantages of each process, as well as CMF samples produced using these methods.

3D Wrapping

Wrapping is a method of applying materials such as fabric, leather, or film to injection-molded products for finishing. It is widely used in various industries including household appliances, automotive parts, and consumer goods. One prominent technique is TOM (Transfer-On-Molding), where adhesive-coated fabric is placed onto the molded part and adhered through heat and pressure. While cost-effective and straightforward, quality control is crucial.

The wrapping method allows for diverse designs using various materials such as fabric, leather, and film, with options for different colors and patterns. Unlike the typical IML process where surface deformations may occur due to injection pressure or temperature, wrapping enables delicate implementation on products without surface distortion. Additionally, it offers protection against scratches, abrasion, and heat, while allowing customization of functionalities like electrical conductivity, waterproofing, and flame resistance. Compared to painting techniques, it also minimizes environmental pollutants emitted.

ⓒhida

Injection molding

Injection molding is a manufacturing process where molten thermoplastic resin is injected into a mold under high pressure to create products of desired shapes. It is a widely used plastic molding method in the production of various items such as automotive parts, electronic components, medical devices, appliance components, and consumer goods.

Injection molding is a technology optimized for plastic materials, allowing for the cost-effective production of a large number of products per unit time using molds. It can accurately produce complex designs, and automation through pre-programming enhances productivity. Moreover, it can mold nearly all thermoplastic materials and reinforce material properties by adding additives and hardeners according to the application.

On the other hand, because molds need to be fabricated for each individual shape, the initial cost is high. Efficiency diminishes for small-scale production below the minimum order quantity (MOQ), and there are limitations on product modifications and alterations.

ⓒhida

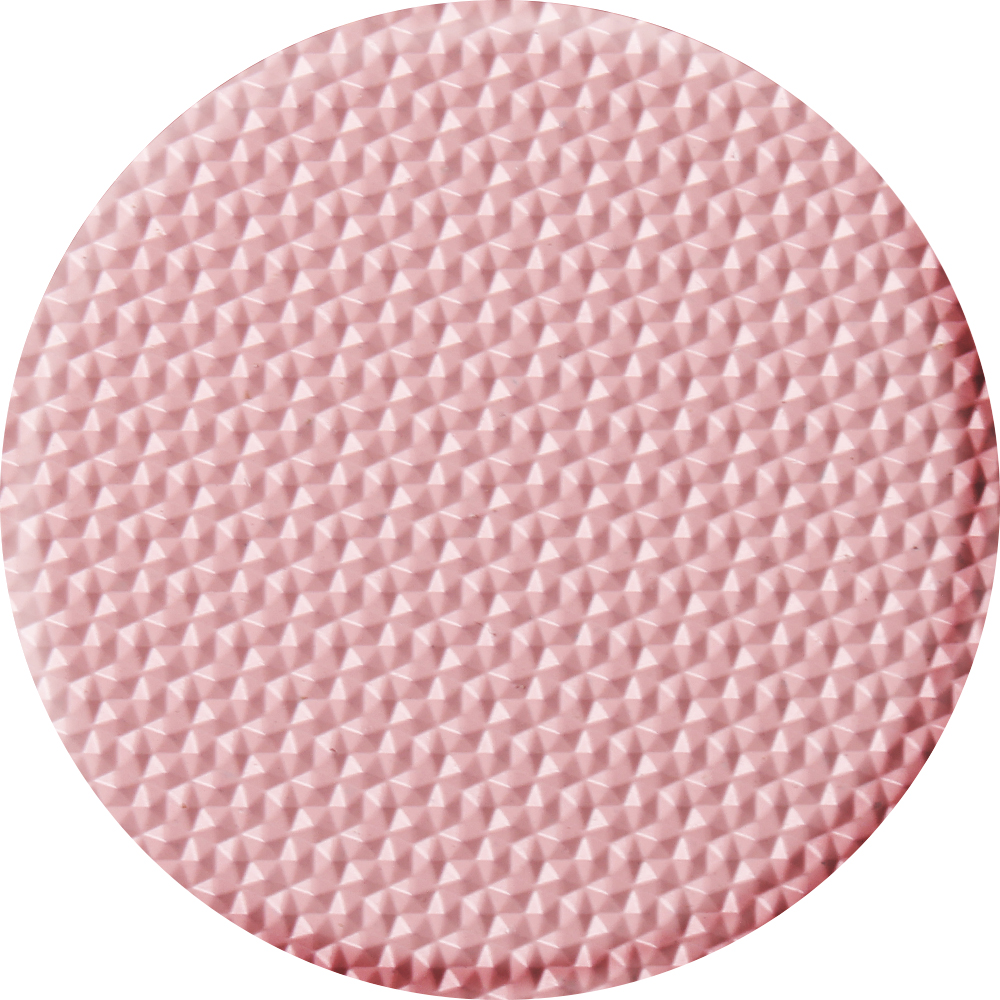

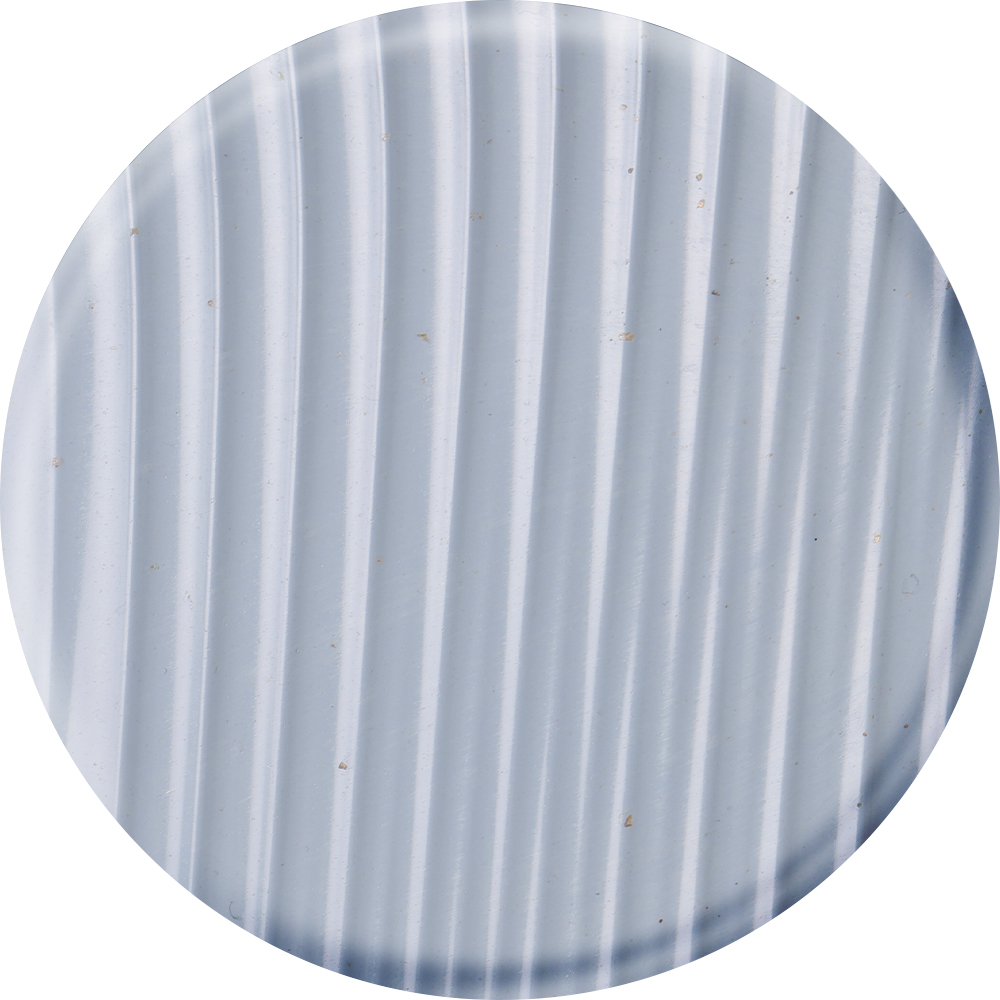

CMF SAMPLE KIT – Sustainable

hida analyzes domestic and international CMF design trends to discover various themes and selects materials that can be widely used in industrial sectors based on them. Through sample kits containing detailed CMF material and technical information for implementing design concepts, you can confirm the innovative technological capabilities of hida.

In the Sustainable theme, we have prepared a diverse range of CMF samples produced through injection molding and wrapping processes. Explore samples themed around CR, BIO, biodegradable materials, eco-friendly composite materials, and vegan leather.

CMF sample kits planned and produced by hida can be directly confirmed and touched when visiting the hida CMF library, where various samples can be compared and experienced. Currently, it consists of 4 themes and 30 categories, with continuous additions planned.

When you visit hida's CMF library, you can not only see CMF sample kits but also directly confirm finished products and parts made with various processes. You can also receive consultations from experts on which CMF processes are suitable for the products you intend to produce.

CMF Library Visit Inquiry >

/

Project Consulting Inquiry >

ⓒhida

All CMF samples shown in the image can be explored for detailed information by clicking the link below.

Save

Save