-

CMF(Color, Material, Finish) Newsletter. 2024.3

Plastic has been an essential material widely used across various industries for a long time. All plastic materials can be produced in various forms, from thin films to thick sheets. The keyword for Hida's March CMF (Color, Material, Finish) newsletter is 'Plastic Film.' This newsletter introduces the types, characteristics, and applicable designs of this material.

Definition and Characteristics of Plastic Film

ⓒgettyimagesbank

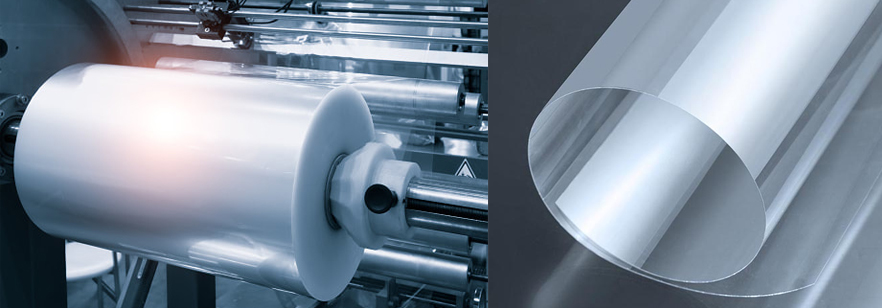

Plastic film is typically made of thin layers of polymer materials and usually has a thickness of around 0.25mm (250 micrometers). This is much thinner than plastic sheets, designed to be suitable for specific purposes. Plastic film is lightweight, cost-effective, and provides excellent chemical resistance and durability. It is easy to transport and install, waterproof, protecting products from moisture and other liquids. Additionally, its flexibility allows for various shapes and applications, and some plastics are recyclable, contributing to environmental protection.

Types of Plastic Film

Plastic films can be classified based on the types of polymers used, and here are some major types categorized by their primary uses.

ⓒwikipedia

Polyethylene Film (PE) is one of the most commonly used plastic films. It has excellent strength and flexibility and is primarily used for food packaging or garbage bags. Medium and high-density polyethylene typically have melting points in the range of 120-130°C (248-266°F), while commercial low-density polyethylene is generally around 105-115°C (221-239°F). Combustion usually occurs above 349°C (660°F), and the color of the film varies from transparent to opaque.

ⓒToray

Polypropylene Film (PP) has high heat resistance and transparency, making it suitable for food packaging and labeling. PP is one of the most versatile plastics with the lowest density, typically melting at 160-171°C (320-340°F). It is sturdy yet flexible, often colorless but can be tinted with added dyes.

ⓒwikipedia

Polyvinyl Chloride Film (PVC) has excellent chemical stability and elasticity, making it one of the most widely used general-purpose plastics due to its low cost. Rigid PVC is used in pipes, window frames, packaging, bank cards, etc., while adding plasticizers makes it flexible. PVC film is typically flexible and transparent, used in interior films and various industrial components.

ⓒSKC

Polyester Film (PET) has excellent mechanical strength and heat resistance, widely used in optical, packaging, electronic, and display components.

Printing Methods for Plastic Film

Various design patterns and colors can be implemented on plastic films like PC or PET films to decorate the appearance of consumer products. Different printing methods are used on the top and bottom surfaces of the film, including silk screen printing, gravure printing, offset printing, and UV imprinting.

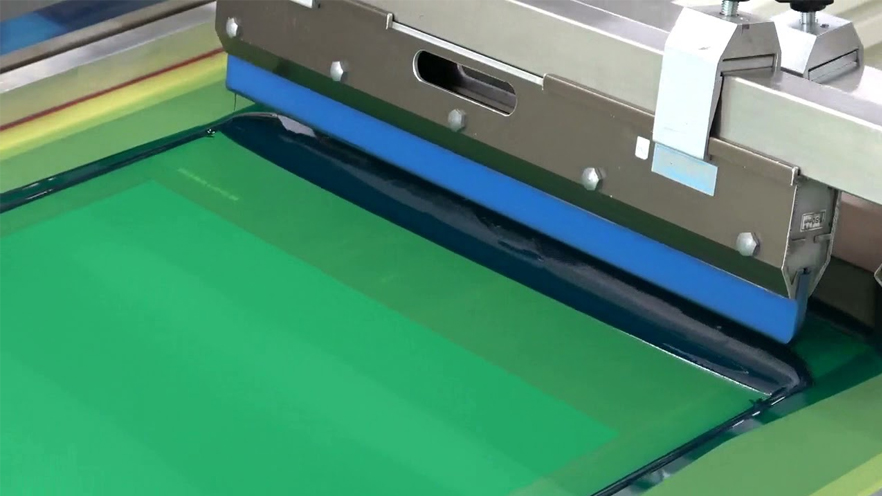

ⓒMINO_screen print

Silk screen printing uses a tight polyester mesh similar to silk to express designs using photosensitive material. Multiple plates are used depending on the printing frequency, providing excellent adhesion and coverage suitable for plastic films.

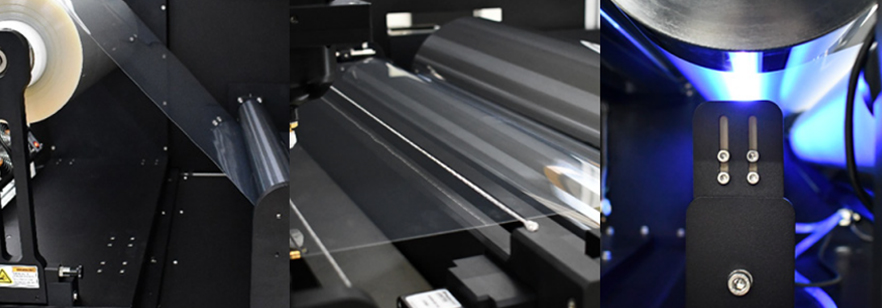

ⓒBeyin Packing_gravure print

Gravure printing transfers ink from engraved metal cylinders or plates with designs into the film using a nip roll. It offers freedom in color intensity and determines color variety based on the number of cylinders, suitable for mass production.

ⓒSOLID impressions_offset print

Offset printing transfers ink applied to a metal cylinder with the design onto the film through rubber rollers. It is advantageous for various materials and mass production, offering excellent color implementation, but requires significant time and cost for setup.

ⓒDCN_imprinting

UV imprinting involves applying UV-curable resin onto the film, passing through a mold, and curing with UV lamps, mainly used for transparently expressing micro-patterns.

Printing Designs on Plastic Film

Designs that can be expressed on plastic film using various printing methods mentioned above are introduced here.

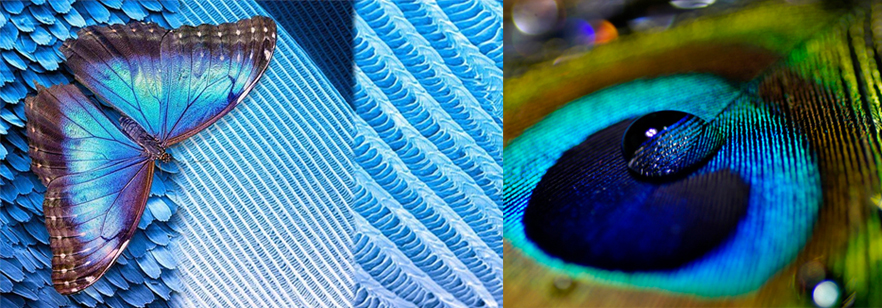

ⓒgettyimagesbank

ⓒLG · Samsung

The first is the 'Iridescent' effect, resembling the rainbow effect seen on the wings of a Morpho butterfly or the feathers of a peacock. CMF utilizing light scattering effects has gained attention in various industries. Materials applied to LG laptops and Samsung's Galaxy A34 smartphones feature printed micro-patterns producing light scattering effects on plastic film.

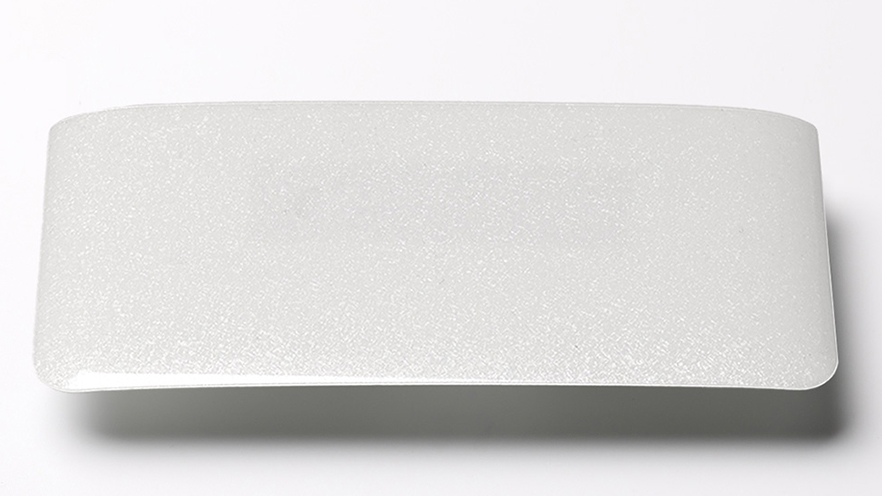

ⓒhida_optical pattern film

Hida has secured mass production technology to apply micro-patterned imprinted plastic films to various product appearances.

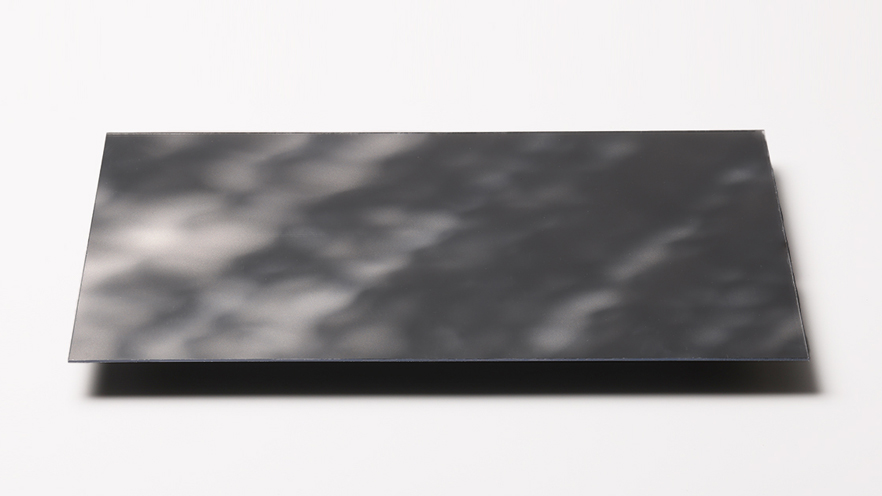

ⓒhida_metallic film

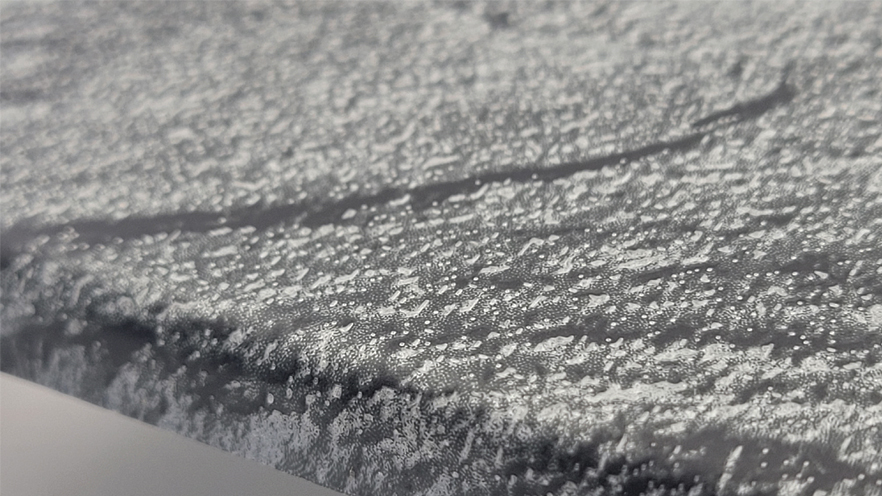

Secondly, the feel of real materials like wood, stone, leather, or metal can be implemented on the film. All methods including screen printing, gravure printing, offset printing, and digital printing can express designs (patterns and colors) identical to real materials and even texture on the film surface.

ⓒhida_wood like film+shy tech display

The mentioned product is a large display window close to 1m in length. When the display is off, the designed graphics are presented like interior objects, and when the display is on, the graphics disappear. Specially printed films inserted on the top of transparent plastic (PC) ensure proper display operation and enable implementation of various designs, including rounded side shapes, with excellent surface hardness and no discoloration, offering various design effects beyond wood.

ⓒhida_stone textured film

ⓒhida_2 Layer Film insert mold

ⓒBuick Envista

The 2 Layer Film insert mold technology, which inserts two films into the mold and injects them, is very challenging. The film inserted on the top ensures the product's surface hardness, while the film inserted below can implement various design effects with different colors and patterns. Hida has successfully mass-produced large display windows close to 1m in length, demonstrating excellent technology replacing glass.

Save

Save